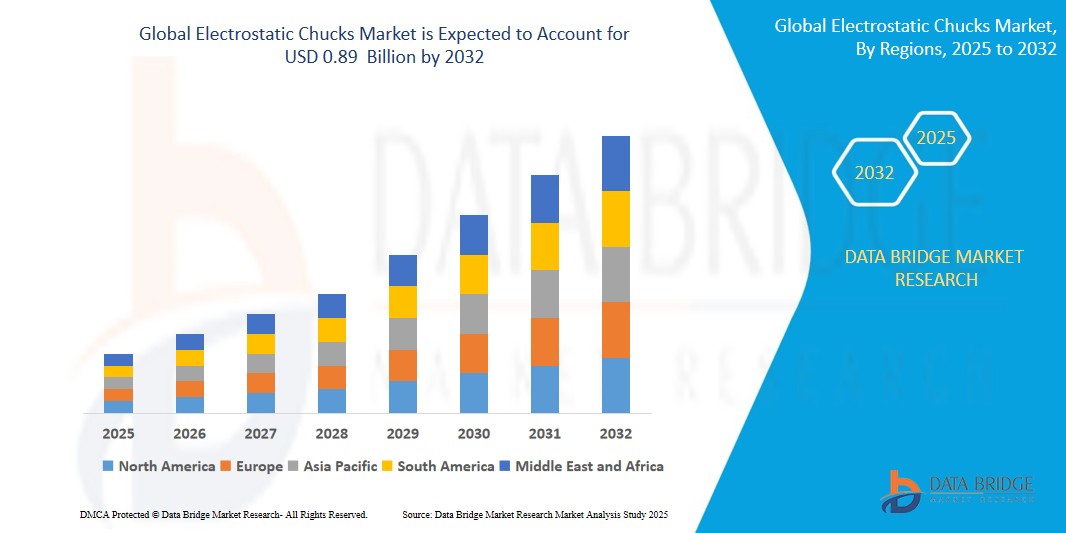

The global Electrostatic chucks market size was valued at USD 0.45 billion in 2024 and is expected to reach USD 0.89 billion by 2032, at a CAGR of 8.9% during the forecast period

Introduction

The electrostatic chucks market is expanding as semiconductor manufacturing, electronics, and advanced material processing industries seek precision solutions for wafer handling and substrate positioning. Electrostatic chucks, which use electrostatic force to securely hold materials in place during processing, are critical components in processes such as chemical vapor deposition (CVD), etching, ion implantation, and plasma-enhanced techniques.

With the rise in demand for smaller, faster, and more energy-efficient devices, Europe’s semiconductor and electronics sectors are driving growth in the electrostatic chucks market. Technological advancements, increasing automation, and stringent quality requirements are further boosting the adoption of these solutions across various industries.

Market Overview

The Europe electrostatic chucks market is witnessing steady growth, supported by innovations in material engineering, precision manufacturing, and automation technologies. Electrostatic chucks are designed to provide uniform clamping force, minimize thermal expansion, and ensure stable handling during complex processing steps.

Applications in semiconductor fabrication, flat panel displays, photovoltaic devices, and aerospace manufacturing are expanding the market’s reach. With rising investment in research and development, manufacturers are developing next-generation electrostatic chucks that offer improved performance, energy efficiency, and adaptability to advanced processes.

Key Drivers of Market Growth

Boom in Semiconductor Manufacturing

The semiconductor industry’s growth, fueled by the demand for integrated circuits, microchips, and consumer electronics, is one of the primary drivers for the electrostatic chucks market. Precise wafer handling is essential for achieving high yields and defect-free production.

Advancements in Process Technologies

As processes such as extreme ultraviolet (EUV) lithography and advanced etching techniques become mainstream, the need for precision tools like electrostatic chucks is intensifying. These technologies require reliable clamping mechanisms that can withstand high temperatures and rapid processing cycles.

Automation and Robotics Integration

The push toward automated manufacturing lines and robotics-assisted assembly is increasing the demand for electrostatic chucks. These devices are preferred for their contactless gripping capabilities, reducing mechanical wear and improving process repeatability.

Stringent Quality Standards

High-performance electronics and aerospace applications demand stringent quality standards to ensure product reliability and efficiency. Electrostatic chucks help manufacturers maintain consistent process conditions, ensuring precision and reducing the risk of defects.

Applications of Electrostatic Chucks

Semiconductor Fabrication

Electrostatic chucks are widely used in semiconductor processing equipment, providing stable and uniform clamping for silicon wafers during deposition, etching, and ion implantation steps. They play a vital role in maintaining wafer integrity and preventing damage.

Flat Panel Displays

In the production of flat panel displays and OLED screens, electrostatic chucks are essential for holding glass substrates and ensuring uniform coatings during manufacturing. Their high precision contributes to improved yield rates and surface quality.

Photovoltaic Industry

Solar panel manufacturing requires consistent positioning and handling of thin-film materials. Electrostatic chucks assist in holding substrates without mechanical stress, facilitating uniform layer deposition and reducing breakage.

Aerospace and Defense

Aerospace component manufacturing involves complex materials and processes that require accurate handling. Electrostatic chucks are used in applications such as laser cutting, component assembly, and surface treatment where precision is critical.

Material Processing

Electrostatic chucks are also used in materials science research and industrial applications that involve delicate or heat-sensitive materials. Their ability to provide uniform force distribution makes them ideal for specialized treatments.

Regional Insights

Germany

Germany’s advanced manufacturing sector and leadership in automotive and electronics production make it a key market for electrostatic chucks. R&D investments and collaborations with research institutions are helping develop next-generation solutions.

France

France’s aerospace and defense industries are driving demand for high-precision tools. Government-supported innovation programs are enhancing the development of advanced processing equipment, including electrostatic chucks.

United Kingdom

The UK’s focus on semiconductor innovation and clean energy technologies is boosting investment in automated manufacturing systems. Electrostatic chucks are increasingly integrated into automated production lines for electronics and aerospace components.

Nordic Countries

The Nordic region’s commitment to sustainability and advanced manufacturing is fostering the adoption of energy-efficient solutions. Electrostatic chucks are being incorporated into manufacturing environments that emphasize reduced energy consumption and process optimization.

Eastern Europe

Emerging markets in Eastern Europe are expanding their semiconductor, electronics, and renewable energy sectors. Investments in modern manufacturing infrastructure are creating new opportunities for electrostatic chuck suppliers.

Challenges in the Market

High Production Costs

The development and manufacturing of advanced electrostatic chucks involve expensive materials and precision engineering, which can increase the overall cost. Balancing cost with performance remains a challenge for suppliers and manufacturers.

Technical Complexity

Designing electrostatic chucks that can withstand high temperatures, resist corrosion, and provide uniform clamping force requires advanced material science and engineering expertise. Integrating these solutions into existing systems can be complex.

Limited Awareness

Some industries still rely on traditional mechanical clamping methods and may lack awareness of the benefits provided by electrostatic chuck technology. Educational initiatives and case studies are needed to showcase efficiency gains.

Supply Chain Disruptions

The sourcing of specialized materials and components may be affected by geopolitical issues, trade barriers, or logistical challenges. Manufacturers must diversify supply chains to mitigate risks.

Future Trends

Next-Generation Materials

Research is underway to develop materials that offer better thermal conductivity, corrosion resistance, and durability, improving the overall performance of electrostatic chucks in high-demand applications.

Integration with Smart Manufacturing

Electrostatic chucks are expected to become integral components in smart factories, where IoT sensors, real-time monitoring, and adaptive controls enhance process efficiency, reduce waste, and improve reliability.

Sustainability and Energy Efficiency

Manufacturers are increasingly focusing on reducing energy consumption by designing electrostatic chucks that operate effectively at lower voltages, without compromising holding strength or performance.

Customized Solutions for Emerging Applications

As industries such as quantum computing, advanced optics, and next-generation photovoltaics expand, customized electrostatic chuck designs tailored to specific process requirements will become a major growth area.

Conclusion

The Europe electrostatic chucks market is poised for substantial growth, driven by advancements in semiconductor manufacturing, aerospace applications, and material processing technologies. With increasing investments in automation, precision engineering, and sustainable practices, electrostatic chucks are becoming indispensable tools in high-performance manufacturing environments.

Although challenges such as high costs, technical complexity, and limited awareness exist, ongoing research, cross-industry collaborations, and regulatory support are helping address these issues. As demand for energy-efficient, reliable, and precise manufacturing solutions continues to rise, the electrostatic chuck market will play a critical role in shaping the future of Europe’s advanced industries.

Frequently Asked Questions (FAQ)

What are electrostatic chucks and how do they work?

Which industries are the largest consumers of electrostatic chucks in Europe?

What challenges are affecting the adoption of electrostatic chuck technology?

How are advancements in materials improving the performance of electrostatic chucks?

What trends are shaping the future development of electrostatic chuck solutions?

Equip yourself with actionable insights and trends from our complete Electrostatic Chucks Market analysis. Download now:https://www.databridgemarketresearch.com/reports/global-electrostatic-chucks-market

Browse More Reports:

Europe Isopropyl Alcohol Market

Europe Kegs Market

North America Kegs Market

Nigeria Modified starch Market

Middle East and Africa Paper Bags Market

North America Paper Bags Market

Europe Passenger Information System Market

North America Polyethylene Glycol Market

North America Polylactic Acid (PLA) Market

Europe Prefilled Syringes Market

EMEA Prefilled Syringes (Saline) Market

India Produced Water Treatment Market

North America Refractories Market

Europe Refractories Market

Middle East and Africa Refractories Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 990

Email:- corporatesales@databridgemarketresearch.com